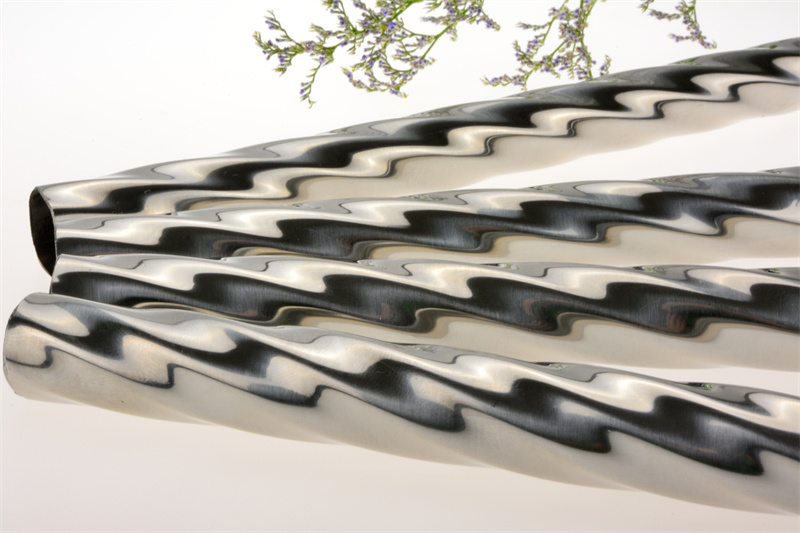

201 202 310S 304 316 Umkhiqizi wamapayipi ensimbi engagqwali ahlotshisiwe ahlotshiswe ngentambo

Ukuhlukaniswa kwamapayipi anentambo:

I-NPT, PT, ne-G zonke ziyizintambo zamapayipi.I-NPT iyintambo yepayipi ye-taper engu-60 ° esezingeni laseMelika futhi isetshenziswa eNyakatho Melika.Amazinga kazwelonke angatholakala ku-GB/T12716-2002m.

I-PT iyintambo yepayipi evaliwe engu-55° evaliwe, okuwuhlobo lwentambo ye-Wyeth futhi esetshenziswa kakhulu emazweni aseYurophu.I-taper ingu-1:16.Amazinga kazwelonke angatholakala ku-GB/T7306-2000.(Isetshenziswa kakhulu ekushiseni okuphezulu, kumasistimu okucindezela okuphezulu kanye nezinhlelo zokugcoba)

I-G iyintambo yepayipi elingavali intambo engu-55°, okuwuhlobo lwentambo ye-Wyeth.Imakwe ngokuthi G imele uchungechunge oluyisilinda.Amazinga kazwelonke angatholakala ku-GB/T7307-2001 (ikakhulukazi esetshenziselwa amapayipi amanzi negesi anengcindezi engaphansi kuka-1.57MPa).U-G igama elijwayelekile lentambo yepayipi, evame ukwaziwa ngokuthi indilinga yepayipi.Okusho ukuthi, intambo icutshungulwa yi-cylindrical surface.I-ZG ngokuvamile yaziwa ngokuthi i-pipe cone, okungukuthi, intambo icutshungulwa ngendawo eyikhoni, futhi izinga likazwelonke limakwe ngokuthi i-Rc (intambo yepayipi yangaphakathi yekhoni).Kokubili uchungechunge lwe-G kanye nentambo ye-Rp kuyimicu yepayipi eyisilinda engu-55°.I-Rp igama lekhodi ye-ISO.

Ingxenye ye-GB yezinga laseShayina ilingana nezinga lamazwe ngamazwe le-ISO.Imininingwane imi kanje:

1. Ukulingana kwentambo yangaphakathi eyicylindrical (Rp) kanye nentambo yangaphandle ecishiwe (R1), ebizwa ngokuthi "ukulingana kwekholomu/ikhoni", inombolo evamile yezwe lami GB/T7306.1-2000, esebenzisa ngokulinganayo izinga lamazwe ngamazwe ISO7-1 : "Ikholomu/ukulingana kwekhoni" ngo-1994 "intambo yepayipi evalwe ngentambo";

2. Ukulingana kwentambo yangaphakathi ecishiwe (Rc) kanye nentambo yangaphandle ecishiwe (R2), ebizwa ngokuthi "i-cone/cone fit", inombolo evamile yezwe lethu i-GB/T7306.2-2000, eyamukela ngokulinganayo indinganiso yamazwe ngamazwe ISO7- 1 : "I-cone/cone fit" ngo-1999 "intambo yepayipi evalwe ngentambo";

3. Ukulingana kwentambo yangaphakathi eyicylindrical (G) kanye nentambo yangaphandle eyicylindrical (G) kubizwa ngokuthi "ukulingana kwekholomu/ukulingana kwekholomu".Inombolo ejwayelekile yezwe lethu yi-GB/T7307-2001 "55 ° intambo yepayipi elingavaliwe".Leli zinga liyalingana Ingxenye yokuqala yezinga lamazwe ngamazwe ISO228-1: 1994 "Imicu yamapayipi angavalwanga" ithi "Dimensional tolerances and marking", kodwa izindinganiso zezwe lami azikukhuthazi ukusetshenziswa kwemicu yamapayipi avaliwe kanye nemicu yamapayipi engavaliwe. , okungukuthi (Rp /G);

1. Amanzi abandayo kanye namasistimu okukhipha amanzi athatha ukuxhuma okunentambo lapho ububanzi bepayipi bungaphansi noma bulingana no-50mm.

2. Umshini wokuhlanganisa ipayipi usetshenziselwa ukucubungula intambo futhi uwoyela okhethekile womshini wokuthunga usetshenziselwa ukugcoba.Amanzi noma ezinye izinto eziwuketshezi azivunyelwe ukufaka esikhundleni sokuthambisa.

3. Amafutha omthofu kanye nocingo lwe-hemp kusetshenziselwa ukuvala nokupakisha kwamapayipi, futhi i-Teflon tape isetshenziselwa ukuxhuma nezinto zokusebenza.Akuvunyelwe ukuletha ukupakisha kupayipi lapho uqinisa intambo.

4. Ukusika ipayipi kufanele kwenziwe nge-cutter noma i-hacksaw.I-acetylene ye-oxygen noma umshini wokusika awuvunyelwe.Ukuphambuka kokuthambekela kobuso bokuphela kokusikwa akufanele kube ngaphezu kwe-1% yobubanzi obungaphandle bepayipi, futhi akufanele kudlule u-3mm.

5. Ukuze kuqinisekiswe ukuthi ubukhulu obuncane bodonga lwempande yentambo, kufanele bugxile kumbuthano wangaphakathi wokuphela kwendawo yepayipi, futhi ukuphambuka kwentambo ye-axial kanye nokutsheka kwe-axial kwentambo yepayipi kufanele kulawulwe ngokuqinile, ngoba kungakhathaliseki ukuthi i-axial parallel deviation noma i-axial tilt deviation, Kokubili kuzonciphisa kakhulu ukushuba kodonga lwamapayipi, ngaleyo ndlela kunciphise amandla epayipi.

Ukuchezuka okuvunyelwe kokucutshungulwa kochungechunge lwamapayipi

Ububanzi bebizo (mm) Ukuchezuka okuhambisanayo (mm) Ukuchezuka kokutshekisa (mm)

1 ≤32 0.3 0.3/100

2 40~65 0.4 0.4/100

3 80~100 0.5 0.5/100

4 125~150 0.6 0.5/100

6. Ngemva kokuba ipayipi elinentambo selicutshunguliwe, lihlole ngethuluzi lokulinganisa elinentambo.Uma kukhona ukufakwa kwamapayipi okucaciswa okufanayo, kungcono ukufanisa ukufakwa kwamapayipi.Izinga lokuxega lidinga kuphela ukufinywa ngesandla, futhi akumele likhululeke kakhulu uma izixhumo zamapayipi zifakwe ngezikulufi. Uma ubhajwa, ungangqongqoza eduze kwepayipi ngozipho lokhuni.Uma namanje singakwazi ukugoqwa noma isikulufu siba siqine, singahoxiswa kuphela.Ukuqiniswa ngenkani akuvunyelwe.

7. Intambo enentambo kufanele ihlanzeke futhi ibe njalo.Intambo ephukile noma engekho akumele yeqe u-10% yenani eliphelele lezintambo.Ungqimba olunothayela endaweni engaphandle yepayipi kufanele luvikelwe.Izingxenye zasendaweni ezilimele kufanele zelashwe ngomuthi wokunqanda ukugqwala.

8. Uxhumo olunentambo Umsuka womucu wepayipi ngemva kokufakwa kwepayipi kufanele ube nemicu esobala engu-2~3, futhi intambo ye-hemp eyeqile kufanele ihlanzwe futhi iphathwe ngomuthi wokunqanda ukugqwala.